Raw Sewage Pump 1 Root Cause Analysis

Date: 2025 07-July 11

Attendees:

Root Cause Analysis

Failure of raw sewage pump # 1

Operator Notes

Last Started 0900 April 1 2025

speed controller at 53 HZ

After discharge valve was able to be opened

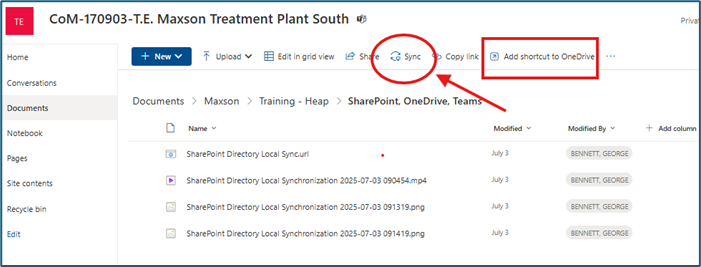

SharePoint Shared Drive Location

raw-sewage-pump-1-root-cause-failure-analysis

If you are locally synced: [Local SharePoint sync](%USERPROFILE%\OneDrive - City of Memphis\170903-T.E. Mason Treatment Plant South - General\Mechanical Maintenance - Knowledge Base\raw-sewage-pump-1-root-cause-failure-analysis)

How to locally sync: SharePoint Documents Local Synchronization

Introduction to the pump, motor, and clutch (mag drive)

Installed in 2002.

1200 horse vertical.

Manufacturer: E+H of Minneapolis, MN.

WEG acquired E+H and basically let them die.

Corrective maintenance program

- Chris Luss: Kim Crawford said every six months

- Chris Luss: It was being done, but then it has been consistently breaking.

How long has # 1 been effectively out of service?

Sewer Line Failure (2015)

- Don: Was raw sewage pump # 1 part of that pumping?

- Mike: Yes, it was. Because 2 and 3 were being installed at the time.

- Mike: We ran 3 pumps in 2015

Sewer Line Failure (~2 years ago, April 2023)

- Don: Was raw sewage pump # 1 part of that pumping?

- Mike: Not sure.

- Chris: I think we were using # 2 and # 3, and then sometimes # 4 when necessary.

- Don: How long has # 1 been effectively out of service?

Clarity, Mike

- It hasn’t run since at least January 2024

Now

- Wait until the Mag comes back from being rebuild externally

- The pump was rebuilt in house, about two weeks ago, to replace the shaft

When the plant was built

- Mike: # 4 was a fixed speed, induction motor. Has not changed.

- Flow matcher control system as used for # 1, # 2, and # 3. Allis Chalmers, GE. This control system was based on an electrolyte solution. It is not longer used in any of the four pump systems.

2000

- Mike: # 1 was changed to a magnetic drive. To increase the HP on the motor and to increase the pumping capacity

- Brand new, it would pump 70 MGD all day long

- Ran well until about 2002 or 2003, with basic PM's

- It was taken out and rebuilt in the early 2000's

Until 2015

- Parts could no longer be found for the old flow matcher system, so # 2 and # 3 were converted away from this in 2015.

- It was a goal to increase the pumping capacity and HP of # 2 and # 3, to 70 MGD each, so the bases for pumps, the motor, and the drives (VFD's) were rebuilt/enhanced/changed. The VFD's is why we have the HVAC building.

Now

- Mike: As we speak (July 2025), # 3 is being diagnosed by a technician from Eaton, who manufactured the VFD's.

- Don: Do we need any upgrades for # 3? Is it under a PM program?

- Mike: I think Chris wants to replace the whole thing.

- Don: Did we miss any opportunities, for monitoring or a maintenance program with Eaton? Did we follow factory recommendations?

- Chris: Yes, we have been involved with them. But not the system is becoming outdated, and the parts are not able to be found anymore. Gary Garrison has been doing the maintenance on the VFD all along

- Don: The other pumps, are they due for maintenance?

- Chris: 2 was taken out to redo the packing, leaving us with 4. And then 4 was taken out for PM / repacking, leaving us with 2. And then they both went out. 4 caught fire after the PM.

- Mike: 2 needs work on the speed control and on the stuffing / packing box on the pump itself. It is leaking from the stuffing box, we think. Once we get another one going, it will need work.

- Don: Why can we not keep three pumps in good shape at all times?

- Chris: That was the case for a while.

Goals

- We should have three pumps available at all times

- Pump 1 took too long to figure out

- We always need three pumps when it rains

Rebuilds

4

- Number 4 motor caught on fire in July 2025.

- Can they rebuild the spare motor (which caught fire) once the parts are taken out?

- Has been a fixed speed pump the entire time.

1

- Mike: Changes are that something got into 1 and caused it to vibrate and caused it to fail.

- Chris: 1 is top heavy.

- Don: if they redesign it, can they put in a more modern motor

- Chris: Harvey Woodall wants to step down the power on that motor.

- Mike: 2 and 3 are also both 1200 HP. 1,2,3 have always been variable.

- Clayton: Was 70 MGD over zealous when the 700 HP motors were all upgraded to 1200 HP.

- Chris: The mag systems don't have to be air condition cooled. Consider throwing away the VFD's. On 2 and 3.

- Don: The base is a totally different geometry.

- Clayton: We don't want to introduce vibration problems if we change 2 and 3 to mags

- Chris: Let's look at Stiles and see how it is set up.

Screen system

- Chris: When the water is high, mass gets past the screens and into the pump, and can cause damage.

- Mike: It has always been that way.

Pumping around the Pump Building

- Mike: There is a change you would have to bypass the pump building and redo the whole thing

- Headworks Piping is in the dry well in the pump station

- The pumps 2 and 3 were done (2015) after the headworks piping was redone (2011)

Screens

- Chris: A screen bypass gate would be useful to close. With this, we don't have climb all the way down in the wet well with active flow just to pull up and fix the rake assembly.

- The rake assembly works automatically. When there is a power failure, the rake assembly gets stuck down there. At this point, someone is required to put on a breathing apparatus to go down there to attach a crane to bring up the screen.

- A bypass around the screen would be helpful to assist in this process, for safety, to recover the rake assembly.

- Additionally, when material builds up on the screen, the wet well can be pumped dry yet there is water behind the screen. The flow just keeps coming and clogging up the screen. This is anther use case for a screen bypass gate.

- While a screen bypass gate would allow debris into the pumps, this is not a major concern, because we have a typical state of water being above the screen (~260 in?) and effectively bypassing it anyways.

- In the case of a new building, we should plan for a screen bypass gate.

Contractors

- Malasari

- AECOM or Gresham Smith

- For replacing the problematic pump system or otherwise engineering a solution.

- Possibly engineer a replacement pump building.