Meeting - BioRem Logs - Past & Future

Don Hudgins:

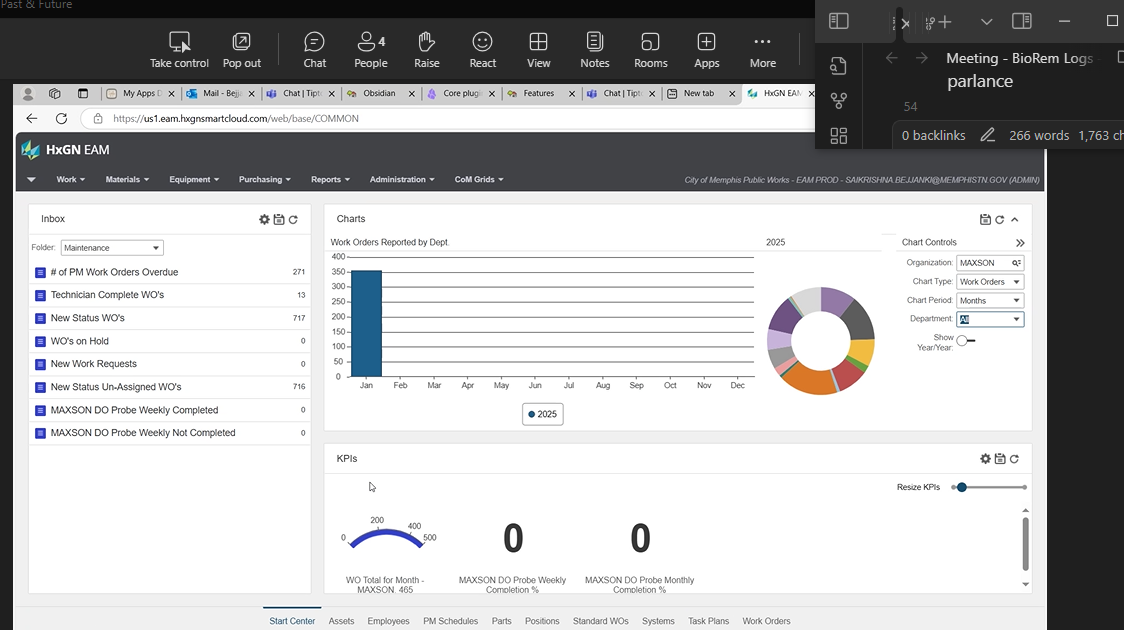

Set up the BioRem in the Hexagon system

In an appropriate way

Need a location code to assign to it people/Mike

Each part of the plant has a location code

Please share in Hexagon a list of codes, Krish

Identify which codes cover the BioRem system

Tag sensors and probes (expect more than 8 in the BioRem, there are thousands in the plant)

A minimum of 34 DO probes

Maintenance can log activity with appropriate

Krish:

Show screenshare of Hexagon

Discussion with people/Rodney Williams

Identify communication failure modes #failuremode , when information is not passed into the system.

Manual notebook (will use in future) needs to be data-entry-ed to Hexagon.

"Gate"

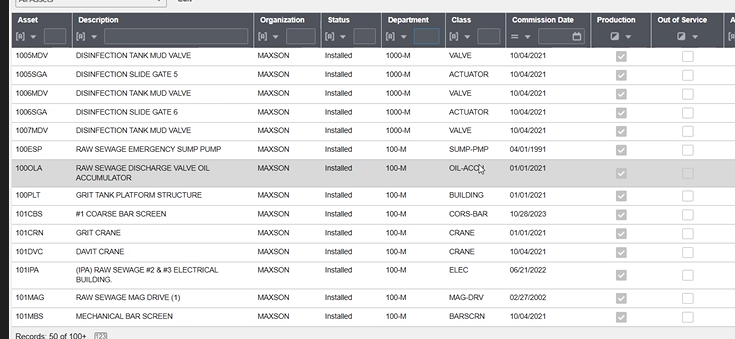

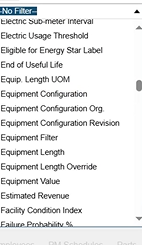

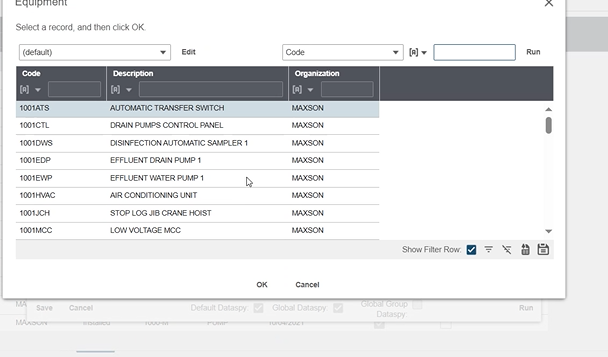

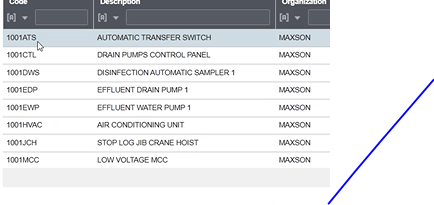

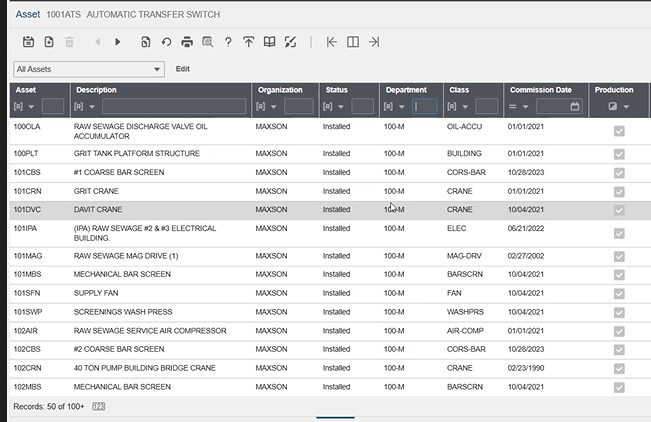

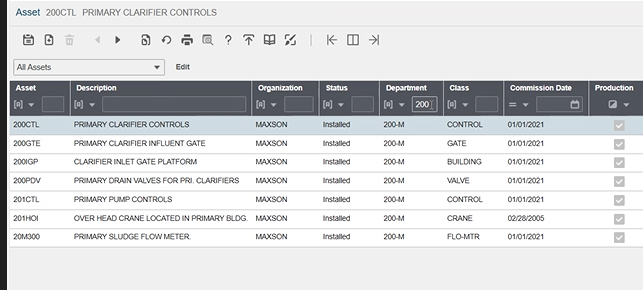

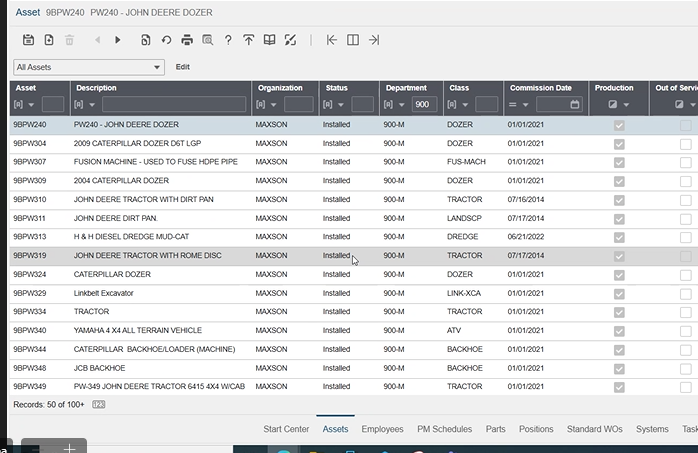

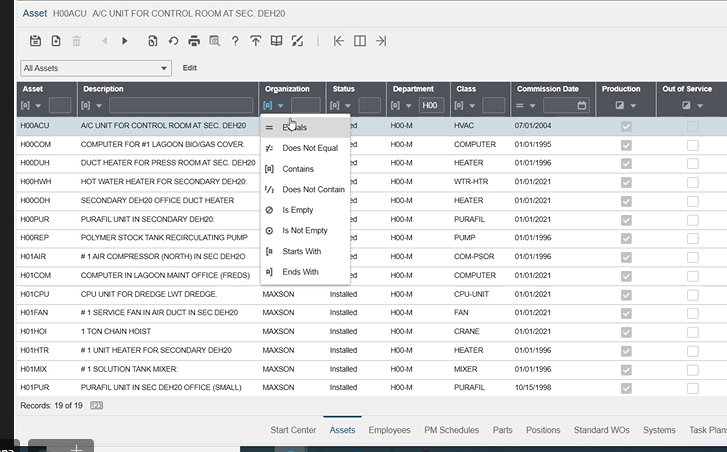

Show listing of equipment: General classification and subclassification.

Asset code example: "1001ATS"

https://us1.eam.hxgnsmartcloud.com/wed/base/COMMON

Department: 1000M

Show full department list:

This shows disinfection "department" (1001):

Work on taking existing data and making it user friendly

limited scope:

"EWP"

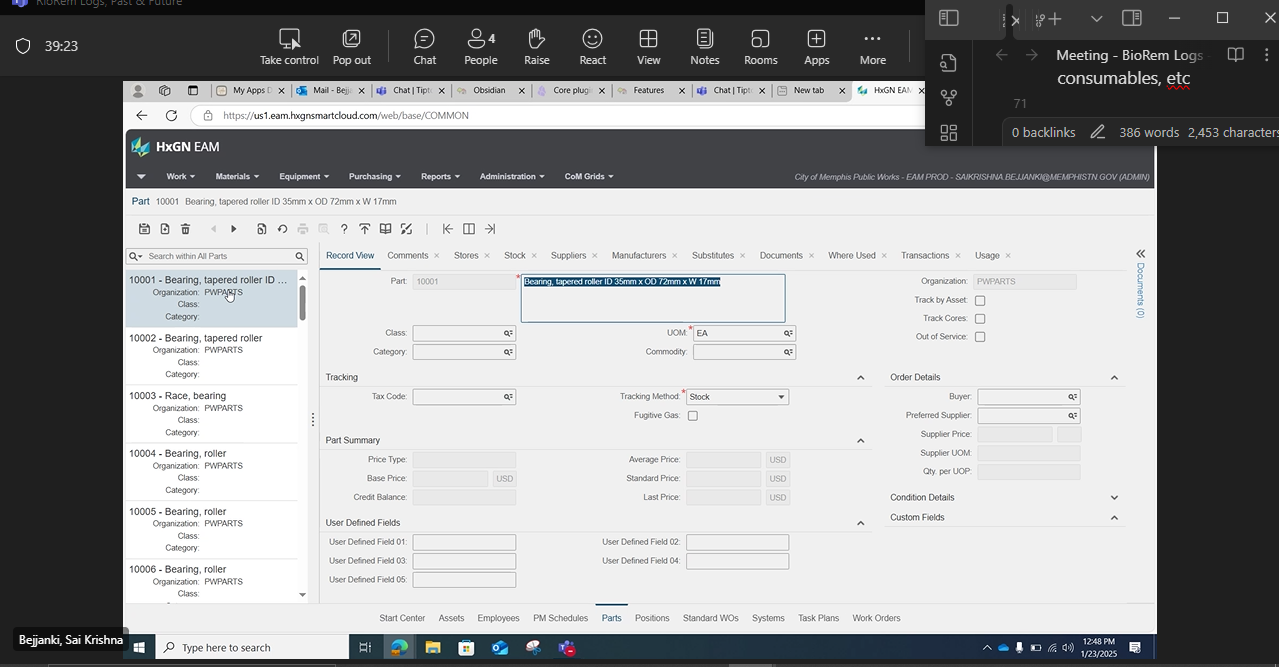

When you buy a piece of equipment, we need to update the asset list, for a consistent way of referring to something - consistent ID for consumables.

NP2 was ported over to hexagon #p2 - Mike

Do it right with BioRem for how we do Hexagon

Foremen will generate a work order for some PM task

Department number is the root number of an asset

200's are primary clarifiers

Rolling stock:

Departments = systems? in Hexagon parlance

"DO probes are the most important probes are the plant"

- What did we buy?

- What has become broken?

- What will happen when we try to turn the system on?

- What are the key improvement opportunities? - low hanging fruit

Krish will add a department in Hexagon, to add BioRem. ANd then add all BioRem components are unique assets

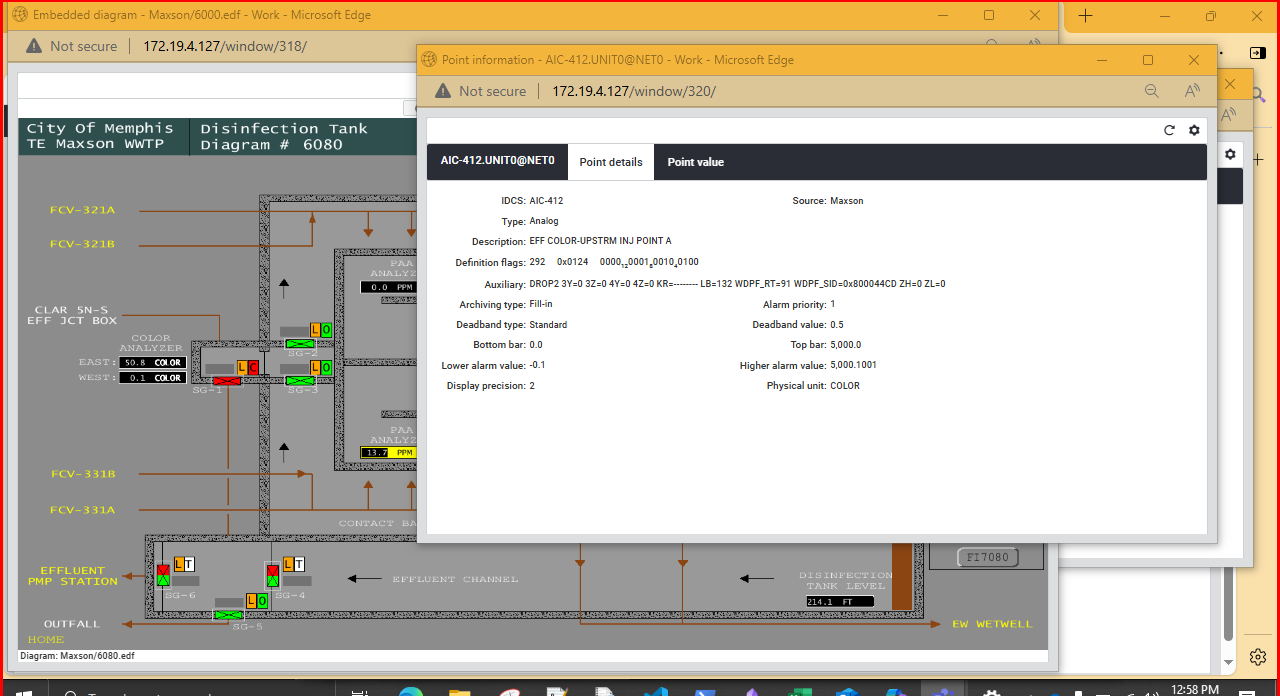

Every unit (ex. tank 1) it reads out to one PLC

The PLC should be connnected to the Ovation system, once we get the fiberline fixed - consider Ovation tags and the unique asset ID's

Look at equipment ID's in Ovation (points) for BioRem equipment

RFID tagging / QR code tagging for spares, consumables, etc

Strictly maintenance, operators will not benefit directly from the Hexagon system - but they can benefit from the Hach Hach WIMS Improvements interface (which will talk to Hexagon)

Operators will be able to enter work request, but will live mostly/entirely on paper:

Goal for Hexagon:

Query equipment records by run hours, temperature, vibration (high-need likelihood cases)

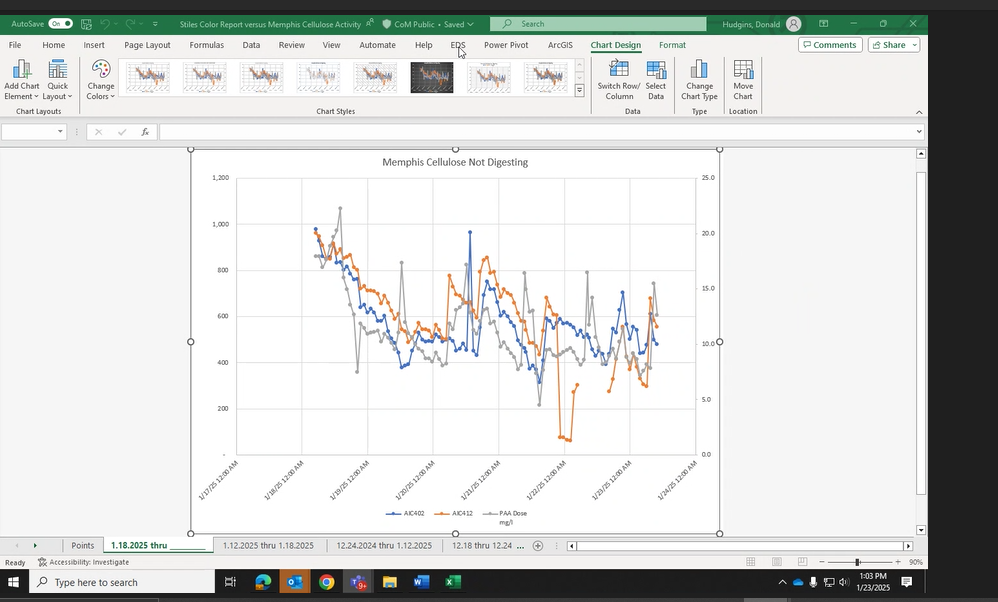

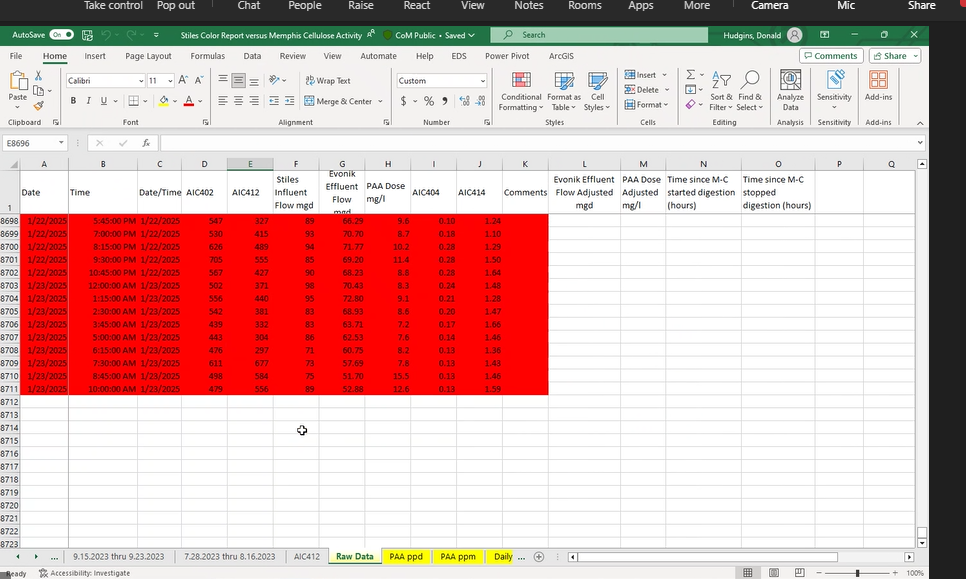

Excel EDS, Don:

- Connect to server (EDS tab)

- Tabular Trend window

- Add cells, hit "okay"

- Go to raw data tab, enjoy

Example: Cellulose activity, in order to assess influent contributions from various industries as they come online

-->Automate! #automate

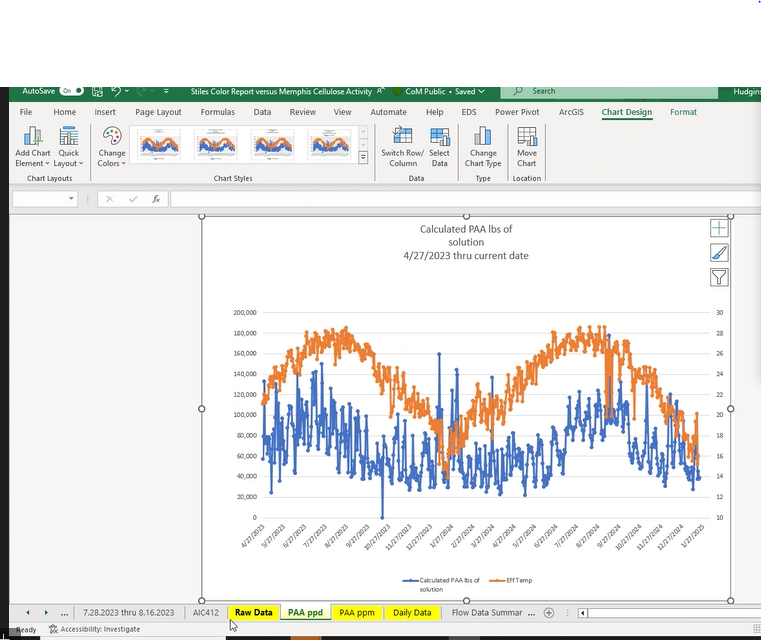

Daily, show averages over time, etc

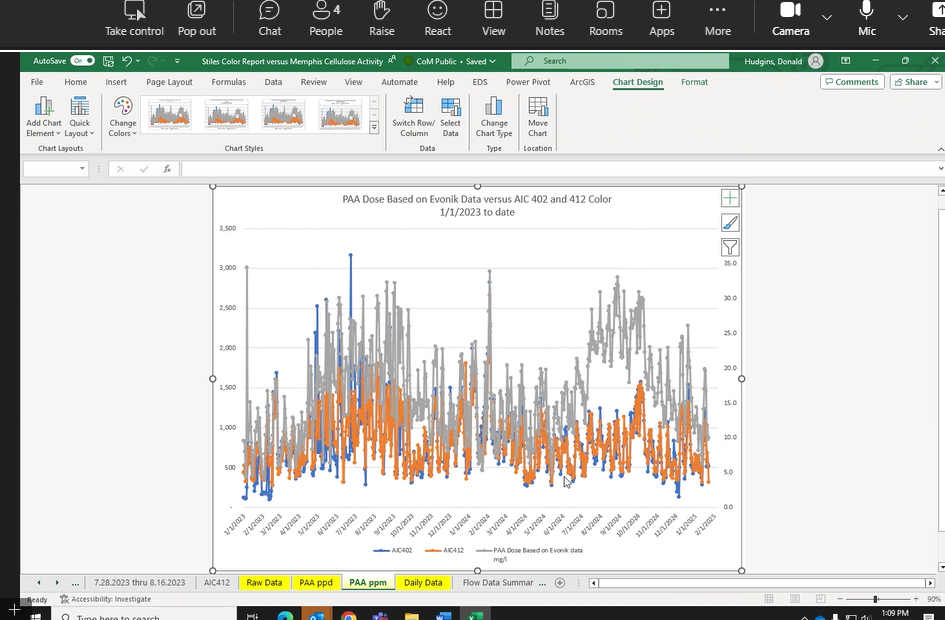

strategy/PAA dosing

Pros and cons to EDS, might be better to access historian, but, use it!

EDS allows for outside access.

Historian has more to access in terms of access.

Key points to analyze and track:

- strategy/PAA dosing from Evonik

- Hargrove sent us a point list for the PAA system

![[HAR-LST01378-EN-CTL-002 Modbus List Rev 1.pdf]]

File: 2024 Annual maintenance accomplishment report.xlsx - get copy from people/Mike on a server. This is an example of the format Don would like to see for the Biogas Flare Reports: equipment history 2023-2024.

Expect to find 10 items or so.

Don's annual reports are on the common drive - the big long 60 page docs

Krish called directly: