Evonik Monthly Review Meeting - 2025_05-July_15

Date: 2025 07-July 15

Gary Clancy speaks first and shares his screen / PowerPoint

Stiles

Don Hudgins: We have not noticed any impact in flows or correlations

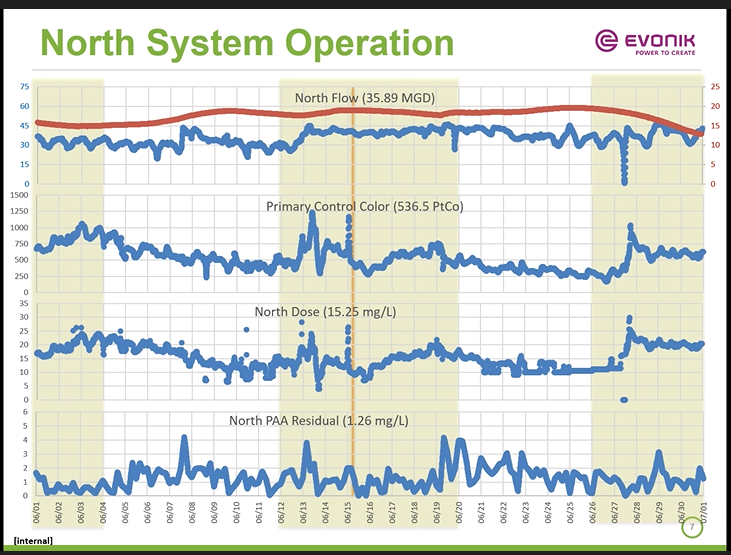

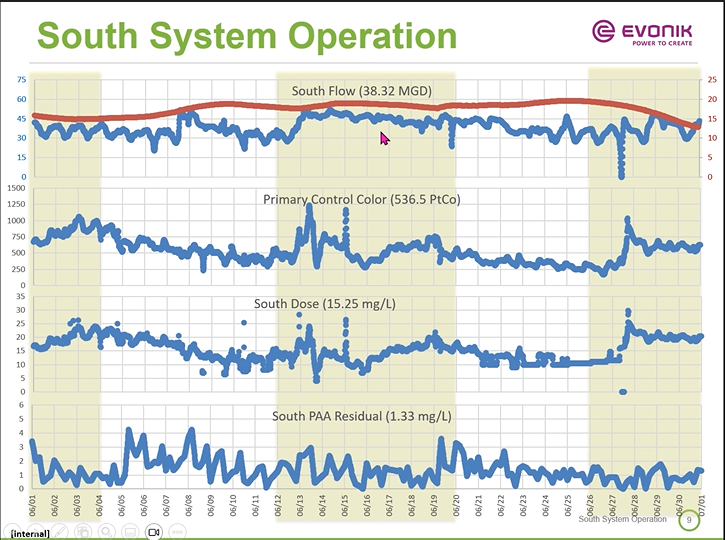

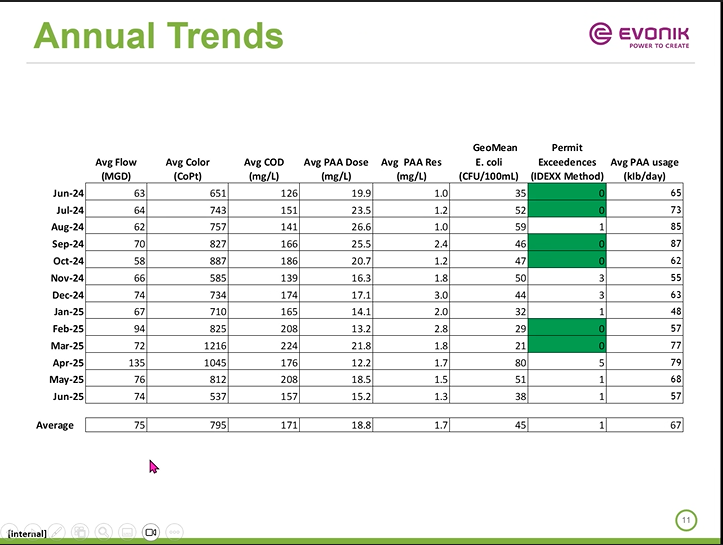

Clancy: We noticed that the South B weir was reading significantly higher readings than the North A weir. Now they are similar. We will keep doing the quarterly calibrations.

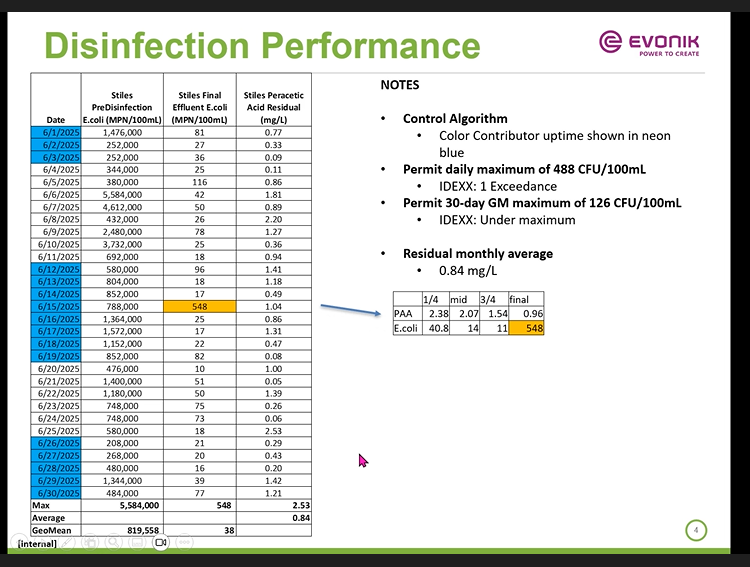

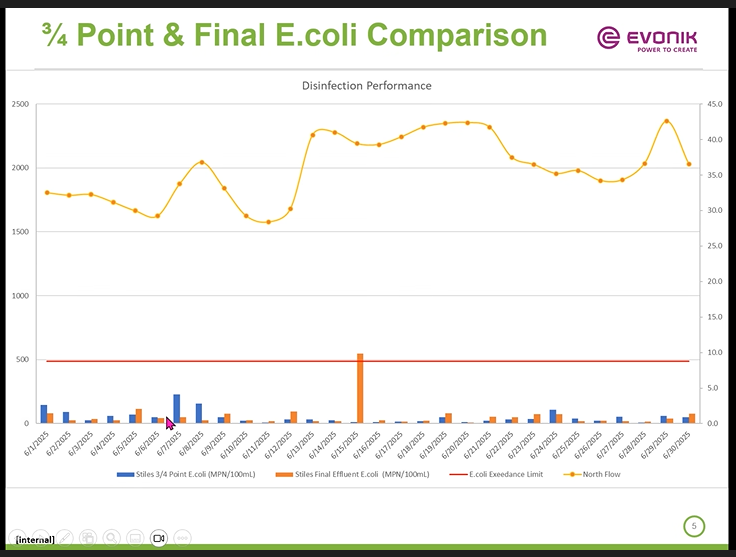

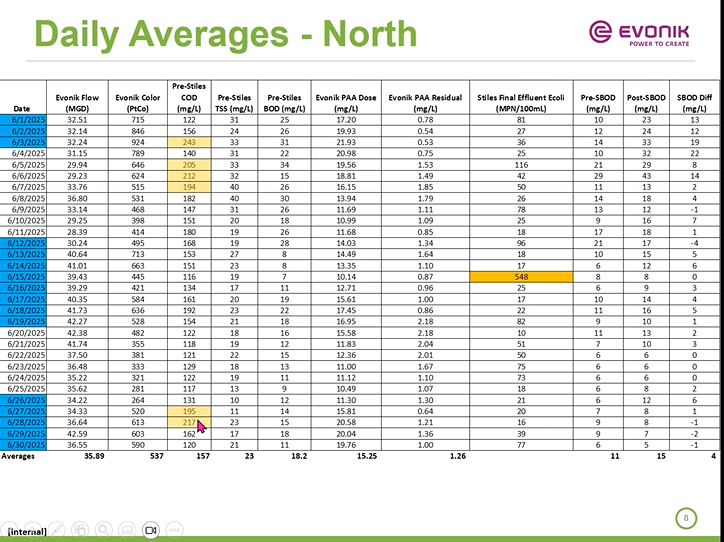

One exceedance on June 15th, with a high E. Coli number: hypothetically erroneous (Henry says there is a 25% chance of a sampling error.)

Residual Monthly Average: 0.84 mg/L

Geomean: 819,558

Low color

High activity from Memphis Cellulose

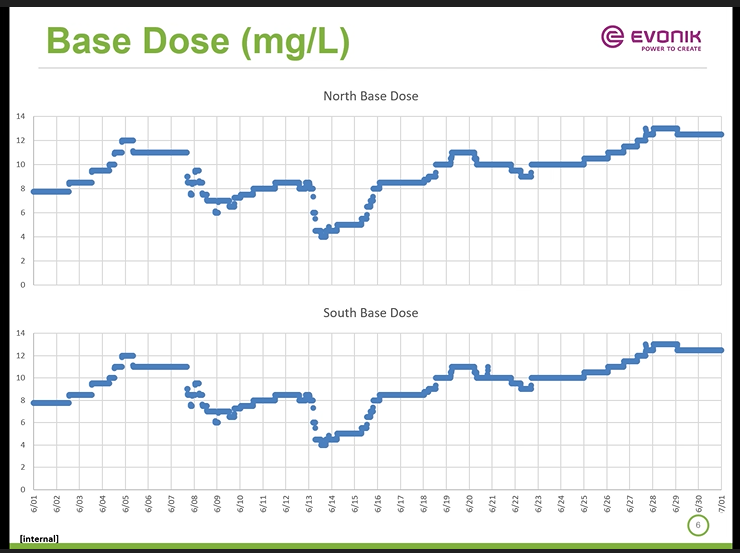

Summer heat is rising. No residual has forced Evonik to increase PAA dosing.

Flow has been very low for June compared to May.

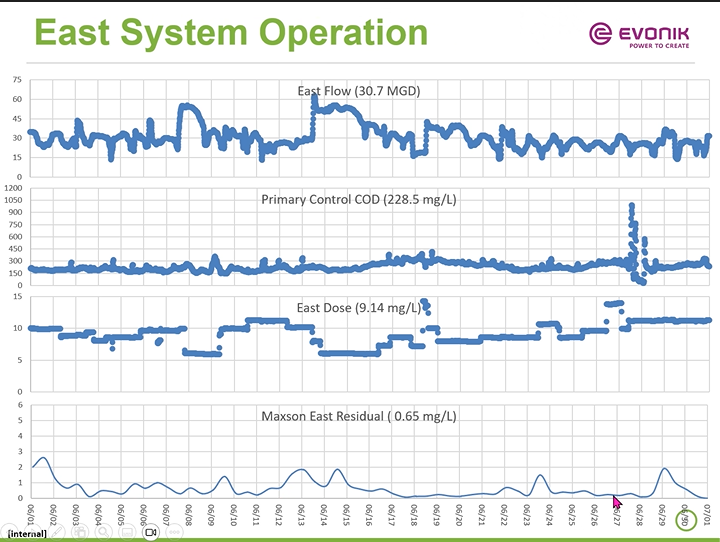

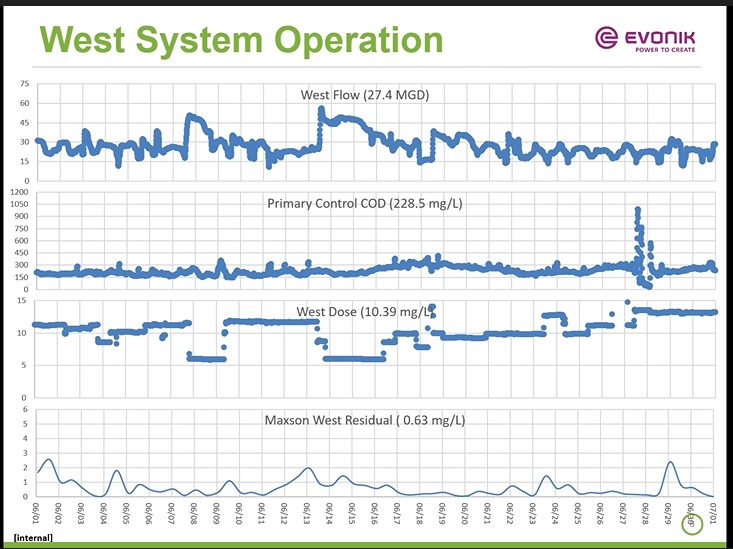

Jon Watson mentioned a power failure at Evonik on June 27th

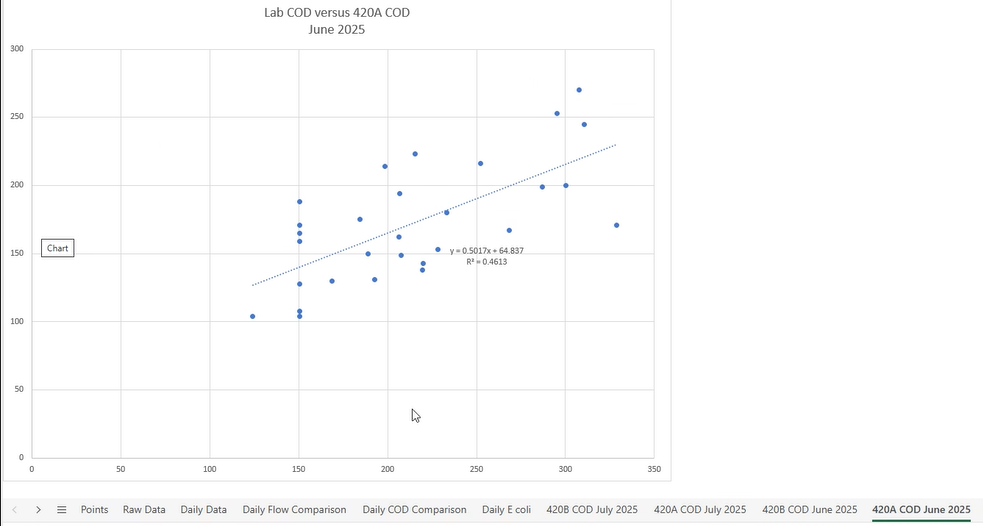

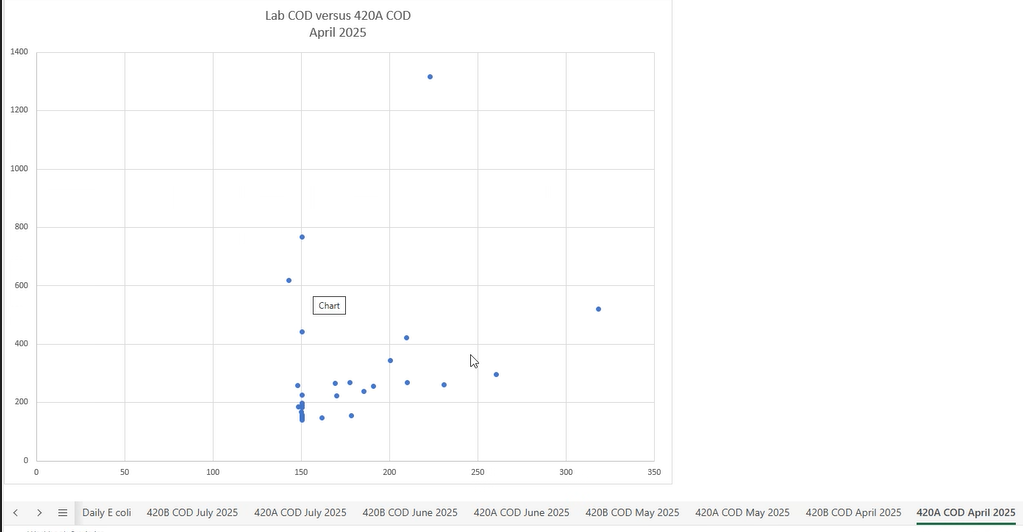

Jon: COD is trending downwards for the Cellulose runtime

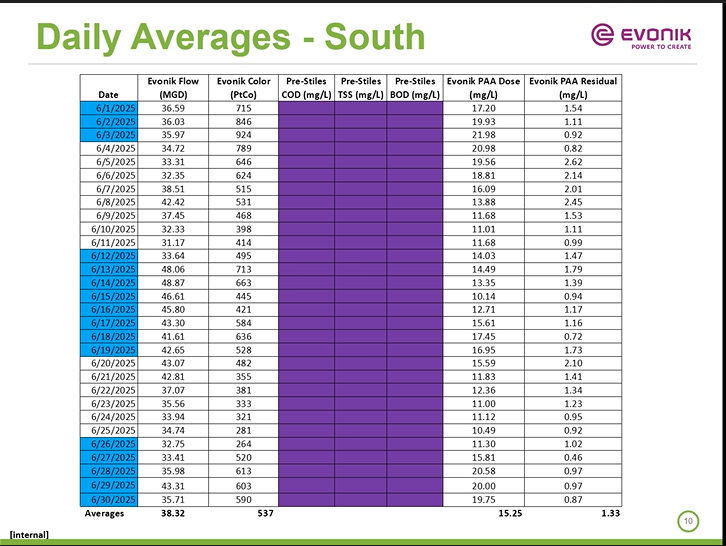

Color was lower than the 800 annual average

157 COD average was low compared to annual 171 average

Henry: It was likely Memphis Cellulose was focused on products that have lighter color in June

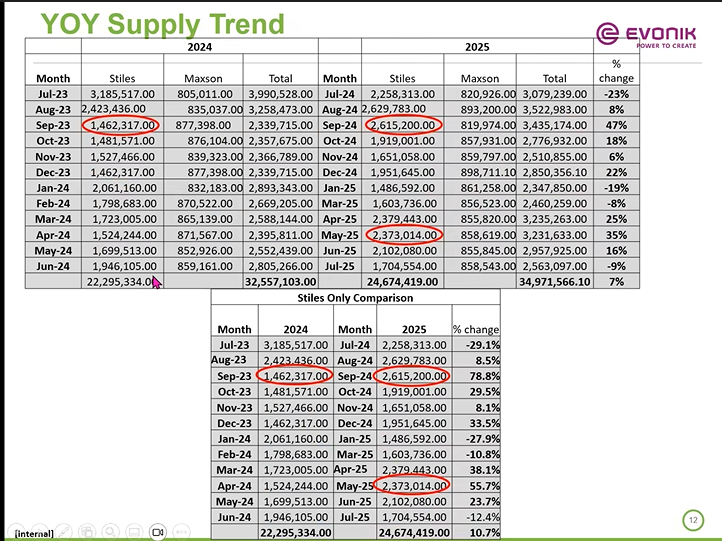

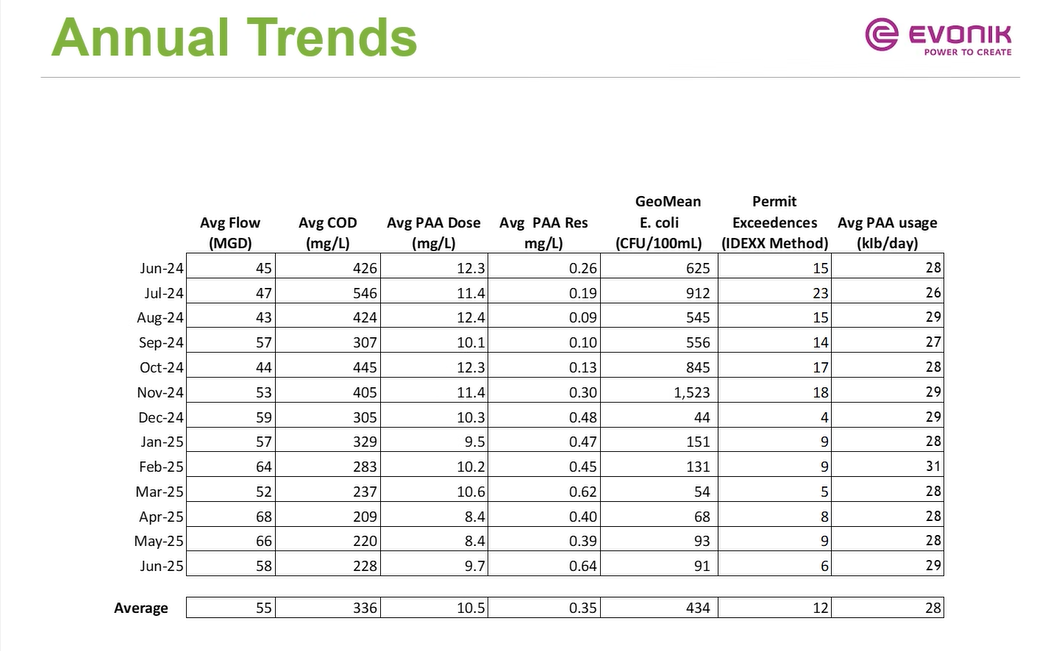

-9% overall (both Stiles and Maxson) on PAA usage compared to the same month last year

Henry: Price per pound of PAA is reducing.

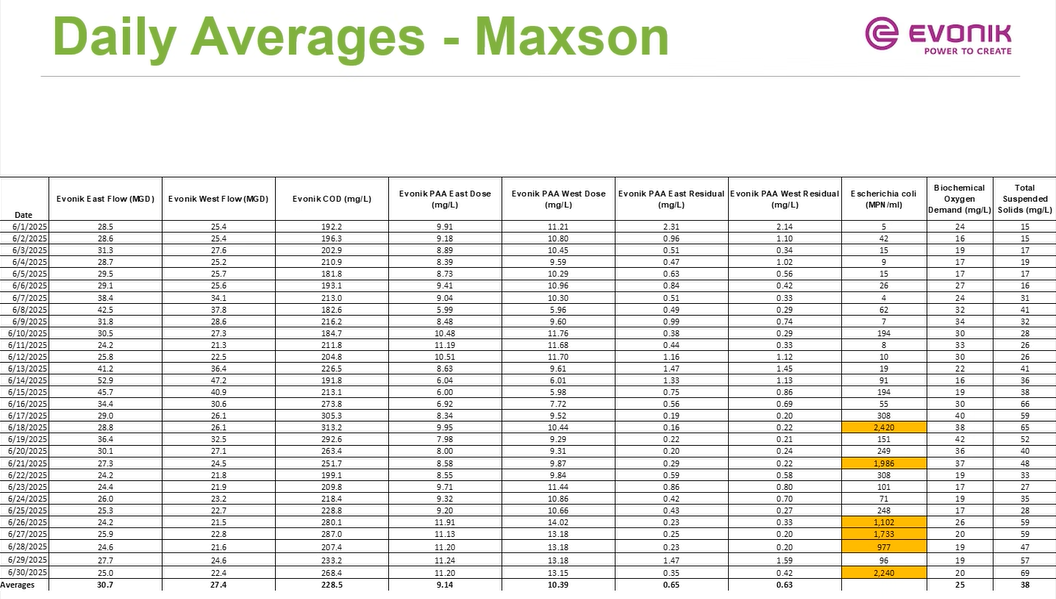

Maxson

We are waiting on two towers to be certified, right now all six towers are running.

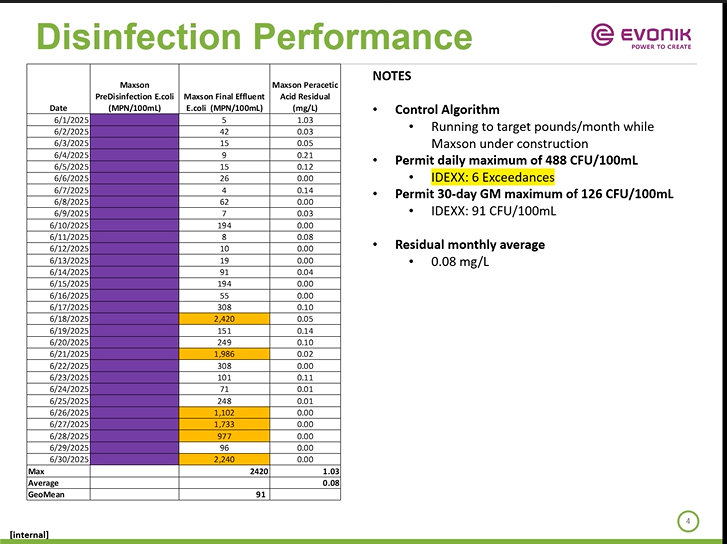

6 exceedances

Geomean of 91

Hach did communicate with Evonik in terms of accurate measurements

Carl Stevenson: we are draining the south side of the plant right now, and we are getting rid of some of the sludge on secondary 5N

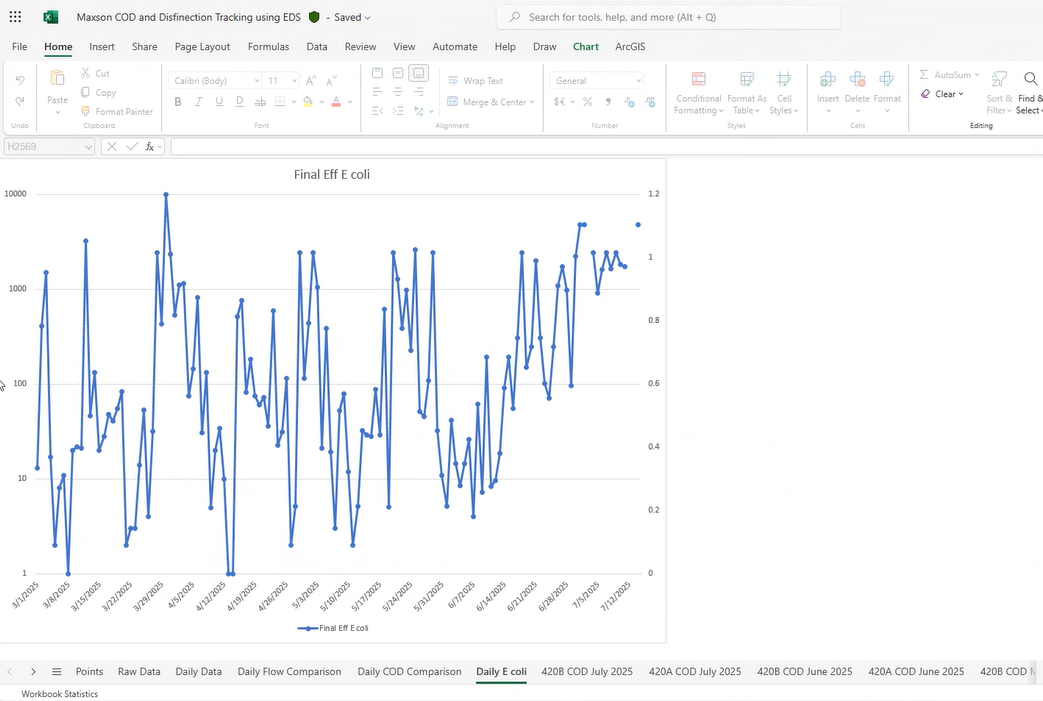

Don shares his screen to demonstrate E. Coli at Maxson

Don: The E. Coli numbers are not following a pattern, in terms of COD.

Gary: Ambient temperature is rising

Don: Effluent TS has ben up a little bit, which might indicate a minor process upset. With sludge rising in secondary clarifiers. But these increases in E. Coli don't relate to the COD coming in. Ideas?

Henry and Chris: Rising sludge in secondary clarifiers. Not entirely settled, but improving each day. It started with the USP peroxide dosing.

Don: Could rising sludge impact the capture, making E. Coli harder to disinfect. It could be protected by the rising sludge.

Carl: When we were dosing the peroxide, our bugs were decreasing. Dead flocc could be protecting the E. Coli.

Don: It appears to be denitrifying. So we don't have the ammonia content going out the back like we used to. We may have increased the PAA demand.

Chris: We have increased the actual solids in the back, which has increased the PAA demand.

Don: We have had an increase in TSS exceedances since the start of July, ever since we started 2025 06-June 27 USP - Maxson headworks odor control project update

#nitrification

#denitrification

#nitrifying

#denitrifying

Don: we must be achieving some sort of anaerobic conditions out there which means we don't have the ammonia content going out the back like we used to. If you smell ammonia, you are killing the nitrifiers.

Carl: The whole denitrification process is oxygen intensive. We expect it to happen in the aeration basin. Daniel, while draining the secondary clarifier tanks, has smelled ammonia smell strongly.

Don: Mike and Don would like Evonik to go on with the COD control in the disinfection tank.

Shoot for September.

Jon says it is meant to be at 150

Don: we are hoping to see more SOC's south of 150

Gary: We will have a discussion with Hach

Henry: Why do so many readings end up at 150

Jon: When we turn off the device it flatlines. This will be resolved in the future.